Evolution® Features

Custom Designed

Electric Fracturing Fleet

Evolution Well Services’ custom designed electric fracturing fleet is powered by a proprietary and patented gas turbine generator package. This ultra-mobile package converts field gas, CNG, or LNG into electricity, resulting in significant fuel cost savings.

Why It’s Better

- Only fully integrated electric fracturing solution provider– fracturing equipment, electrical integration, power generation, and gas processing

- Remote equipment operation reduces personnel exposure

- 50% smaller footprint than a conventional frac fleet

- Emissions levels well below Tier IV thresholds

- Eliminates NPT associated with maintenance intensive diesel engines, transmissions and hydraulics

Evolution’s Electrical Safety and Power Management

- Fail-safe logic for all energized circuits

- Multiple layers of software and hardware safety mechanisms in place

- Advanced variable frequency drive technology enables precise operation and power conservation

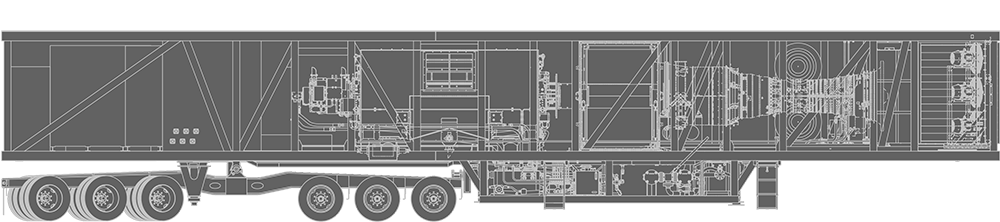

Turbine Generator

Expand Details

Evolution Well Services’ 100% electric frac fleets are packaged into ultra-mobile, built for purpose, hydraulic fracturing power generation units. We are a certified OEM packager for GE’s LM2500+G4 line of gas turbine engines.

- This mobile package yields pad move times of < 24 hours – no crane or forklift required for set up

- The LM2500+G4 engine exhibits a 25,000 hour service interval vs. a diesel engine service interval of 8,000 hours

- Turbine package is designed to allow for rapid response to power demand changes

- Two trailers operational and transportable

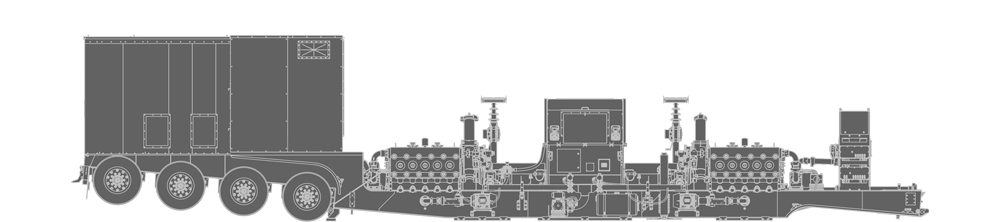

Dual Pump Unit

Expand Details

- 7,000 hp AC continuous duty motor with on-board variable frequency drive

- 2x – 3,500 HHP Quintiplex Well Service Pumps

- Independent pump disconnect allows individual pump isolation and operation

- Ergonomic trailer design allows for safe and efficient fluid end maintenance

- Simple plug-and-play equipment connection – single cable supplies both power and communication to each piece of equipment

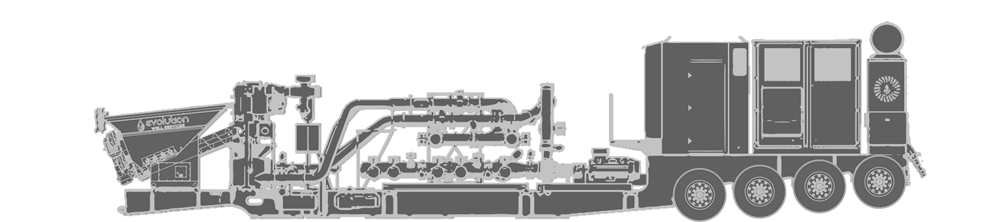

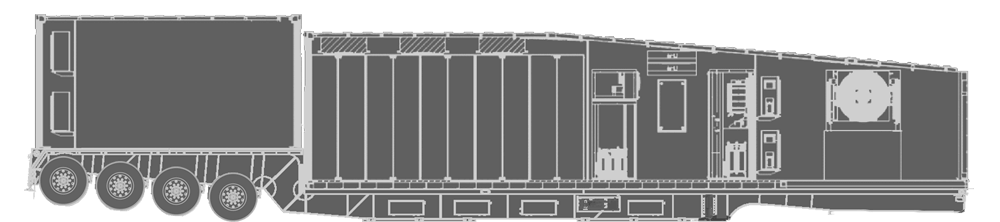

Dual Blender

Expand Details

- No operator station on blender eliminates personnel exposure to silica dust, chemicals and the high pressure zone

- Each side of the blender can be programmed to run 120 BPM independently or 240 BPM in combination , providing unique job design flexibility

- Full redundancy on single trailer enhances operational efficiencies and reduces footprint compared to conventional back-up blender requirements

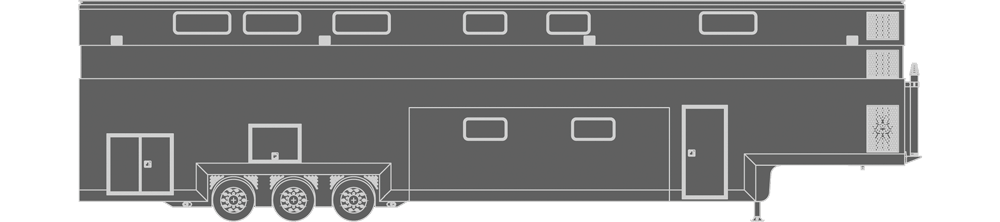

Data Van

Expand Details

- Three-level data van with first-level exclusive client lounge

- Equipment is operated from top level with a bird’s eye view of location

- All equipment on site is operated from the safety of the data van

- 360 degree eye-in-the-sky camera system

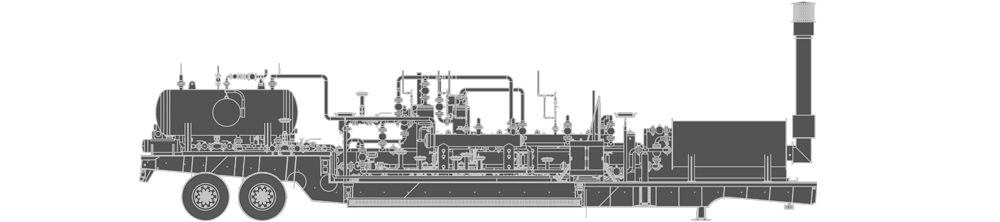

Gas Conditioning Skid

Expand Details

- Treats field gas, CNG, or LNG at flow rates capable of producing 70 MW

- Handles a wide range of BTU content Field Gas resulting in maximum fuel flexibility

- Full replacement of Diesel with Field Gas can deliver over 90% fuel savings for customers

- In-house design, support, and customized solution meeting customer specific needs

- Custom programming maximizes reliability through integration of gas conditioning skid and power generation

Battery Energy Storage System

Expand Details

- Fully integrated energy storage system with mobile trailer design

- Ventilation and hydraulic auto leveling systems for quality control purposes

- Long life cycle with performance at temperatures as low as -30 C

- High power density and inherently safe with no fire suppression required

Reciprocating Engines

Expand Details

- Auxiliary power source to provide reliable back up power

- Advanced automation features to optimize fuel consumption, and emissions

- High system efficiency

- Engineered with flexibility in mind for varying operating conditions

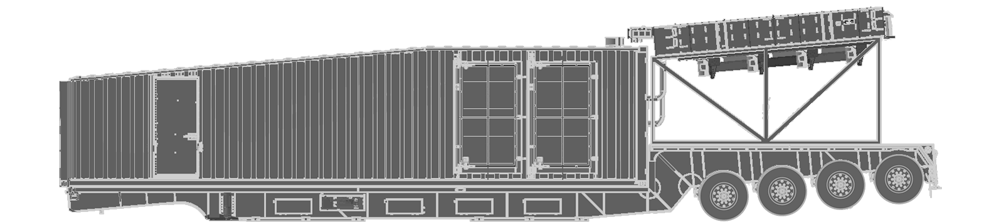

Flexible Hose and Large Bore Solutions

- Minimizes connections in high pressure flow system, limiting failure points

- Completely eliminates traditional treating iron from frac operations

- Equipment is lifted mechanically, reducing risk of personnel injuries

- Location footprint is concentrated, allowing for clear access routes and decreased hazards